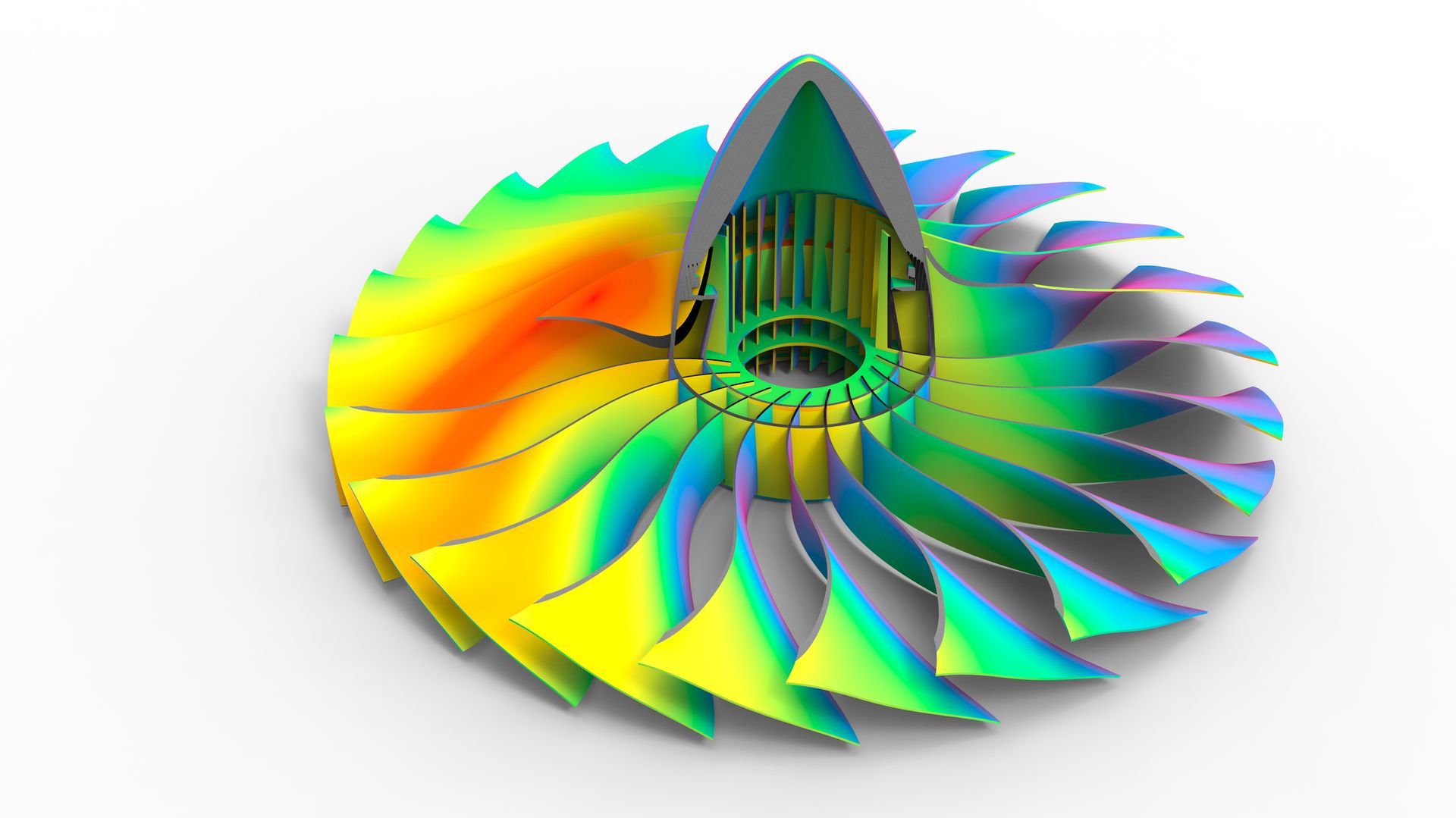

Many engineers tell me the same story after their first encounters with Finite Element Analysis. They spend hours setting up a model, carefully applying loads, constraints, and material properties, and when the solver finally runs, they stare at the colorful contour plots with mixed emotions. On one hand, there is excitement at seeing the results. On the other hand, there is doubt. Can these results be trusted? Do they reflect reality, or are they just numbers produced by a machine?

This doubt is natural. FEA is a powerful but complex tool, and without a structured approach, it can produce results that are misleading. Confidence in FEA is not built by trusting software blindly. It is built step by step, by applying engineering fundamentals, by verifying assumptions, by validating against reality, and by cultivating habits that separate reliable simulations from false comfort. In this article, I want to show you how engineers can build that confidence, and why it is essential for professional growth.

Starting with Fundamentals

The first foundation of confidence is engineering fundamentals. No matter how advanced the software is, nothing replaces a quick calculation done on paper or in a spreadsheet. Simple beam theory, plate equations, or basic stress analysis provide order-of-magnitude checks. When your FEA model predicts a deflection of 10 mm and your hand calculation suggests 1 mm, alarm bells should ring.

I often tell my mentees that FEA should not be the first calculation you make, but the last. The role of FEA is to refine, to capture complexities, to explore variations. But its credibility comes from agreement with simpler models. If you cannot check your work against first principles, you cannot be confident in your results.

Verifying the Model Setup

Confidence also depends on knowing that your model reflects reality. This means paying attention to boundary conditions, materials, and connections. Too many engineers stabilize a model with artificial constraints just to make it run. They forget that every constraint changes the load path and the stresses. Similarly, small mistakes in material properties, wrong units, missing nonlinear behavior, incorrect temperature dependence, can invalidate the entire analysis.

Contacts and connections are another common source of error. A bolt modeled as fully fixed gives a very different response than a bolt modeled with compliance or contact. A gap modeled as glued contact may show no separation when, in reality, detachment is inevitable. Each of these details can swing results dramatically, and confidence only grows when you know your model matches the physical setup as closely as necessary.

The Importance of Mesh Convergence

FEA is built on discretization, and the mesh is at the heart of it. An inexperienced engineer may create a fine mesh everywhere, believing that more elements automatically mean better accuracy. But this is neither efficient nor sufficient. The real test of accuracy is mesh convergence. By refining the mesh in areas of interest and observing whether stresses or displacements stabilize, you know whether your solution is reliable.

Confidence comes not from a single result, but from seeing results stabilize as the model improves. A contour plot from a single mesh can be misleading. A trend across mesh refinements gives you certainty. I encourage every engineer to build the habit of mesh verification, even on simple models. It is the best insurance against false confidence.

Interpreting Results with Caution

Even with the right setup and a converged mesh, results must be interpreted carefully. FEA is notorious for producing stress singularities, those infinite spikes at sharp corners or point loads. Beginners often panic when they see stresses higher than material limits at such locations, but experienced engineers know these are numerical artifacts. The important question is whether the stress field away from singularities is realistic.

Similarly, averaged or nodal stresses may tell a more reliable story than peak elemental values. Hot spots must be distinguished from genuine weak points. Confidence in results grows as you learn to separate artifacts from reality. It is not about trusting the first number you see, but about reading results like an experienced interpreter of a language, knowing which words carry meaning and which are noise.

Validation Against Reality

Ultimately, confidence comes from validation. Whenever possible, compare your simulations to experimental results. Even if you cannot test the exact structure, benchmark your methods against standard problems or published studies. If your simulation of a simple beam or plate matches known solutions, you gain confidence in your approach.

Validation is also about correlation. You may not match every test point perfectly, but you should capture the right trends. If your simulation consistently underpredicts stiffness or overpredicts strength, you can calibrate. If it shows completely inconsistent behavior, you know something fundamental is wrong. Confidence grows when you see that your model aligns with reality in a systematic way.

Sensitivity and “What-if” Studies

Another powerful way to build confidence is to explore sensitivity. Change a boundary condition slightly, modify a material property, or alter a load, and see how the results respond. If small changes produce stable, consistent results, you know your model is robust. If tiny variations cause wild swings in output, you know your model is fragile and untrustworthy.

This habit not only builds confidence but also deepens understanding. By testing “what if” scenarios, you learn how loads travel, how geometry influences stresses, and how assumptions matter. The engineer who knows the sensitivity of their model is always more confident than the one who takes results at face value.

The Role of Peer Review and Mentorship

Confidence is not built in isolation. Having another engineer review your model can reveal blind spots you did not see. Mentors and peers bring fresh perspectives, catching mistakes in boundary conditions, mesh, or interpretation. More importantly, they provide reassurance when your approach is sound. Nothing builds confidence like hearing an experienced engineer say, “Yes, this setup looks correct.”

This is why mentorship is central to FEA practice. Left alone, young engineers may question themselves endlessly. Guided by a mentor, they learn which doubts are valid and which are unnecessary. Over time, this external validation becomes internal confidence.

Documenting Assumptions and Limitations

Confidence also comes from transparency. By clearly documenting your assumptions, what loads you applied, what simplifications you made, what effects you ignored, you build a record that others can review and trust. Paradoxically, admitting limitations strengthens credibility. When you say, “This model does not account for weld fatigue, but it accurately captures static stiffness,” you show you understand both the strengths and the boundaries of your work. Confidence is not about claiming perfection but about demonstrating clarity.

Conclusion: Confidence Through Rigor

Confidence in FEA does not come from trusting software defaults or producing colorful plots. It comes from rigor. It comes from grounding results in fundamentals, verifying setups, testing mesh convergence, interpreting results critically, validating against reality, exploring sensitivities, and seeking review.

Engineers who follow this path do not just run simulations; they deliver decisions. They can stand in front of managers, clients, or regulators and defend their results with authority. That authority is what transforms FEA from a technical exercise into a tool of engineering leadership.

At FEA Academy, we believe building confidence is as important as building skills. Our mentoring programs are designed to guide engineers step by step through this process, ensuring they not only know how to model but also how to trust and defend their results. Confidence is the ultimate outcome of good FEA practice. And with confidence, engineers can use simulation not just to analyze designs, but to shape the future of engineering itself.