"The limitations of the human mind are such that it cannot grasp the behavior of its complex surroundings and creations in one operation. Thus, the process of subdividing all systems into their individual components, whose behavior is readily understood, and then rebuilding the original system from such components to study its behavior is a natural way in which the engineer, the scientist, or even the economist proceeds."

What is

Finite Element Analysis?

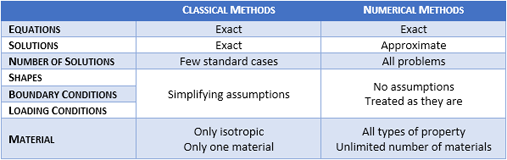

The Numerical Methods

To solve complex problems, the mechanical engineers use numerical methods. The four common numerical methods used to solve engineering problems are:

- The Finite Element Method (FEM)

- The Boundary Element Method (BDM)

- The Finite Volume Method (FVM)

- The Finite Difference Method (FDM)

All these methods can be used to solve the same problem; however, substantial differences exist among the methods with respect to the accuracy of results, ease of programming, and computation time. When internal details are required such as the stresses in a part, BEM gives poor results, as it only considers the outer boundaries. In this case, another method such as the finite element method, FDM, or FVM is preferred. FVM can be used for solving stress problems, but it is preferably used to solve computational fluid dynamics problems. FDM has limitations when it is used with complicated geometry, assembly of different material components, and the combination of various types of elements (1D, 2D, and 3D). To solve complex mechanical problems, the finite element method is, by far, the best method in terms of accuracy and computation time.

The Finite Element Method

The first step of the FEA process consists in creating a computer model of the geometry of the real object which is to be analysed. Next, the analyzed part is segmented into a huge number of individual elements (usually hundreds of thousands) with basic shapes such as squares or cubes. Material properties are assigned to each element and this model is subjected to various conditions, such as external forces or loads. Mathematical equations predict the behavior for each of the elements and, using computational methods, all of these behaviors are combined. This combination permits to predict the overall behavior of the analyzed part.

During a structural simulation, the Finite Element Method permits the engineers to compute the stiffness and the strength of the analyzed structure, allowing the visualization of the displacements and the distribution of the stresses and strains inside the structure. It is used to solve problems of engineering.

Finite element analysis is now used routinely to solve problems in the following areas:

- Structural analysis

- Thermal analysis

- Vibration analysis

- Stability problems

- Design optimization

- Dynamic analysis

- Metal forming

- Crash simulation

- Fluid flow

- Structural interaction with fluid flows

- Shock analysis

- Acoustics

- Electromagnetics

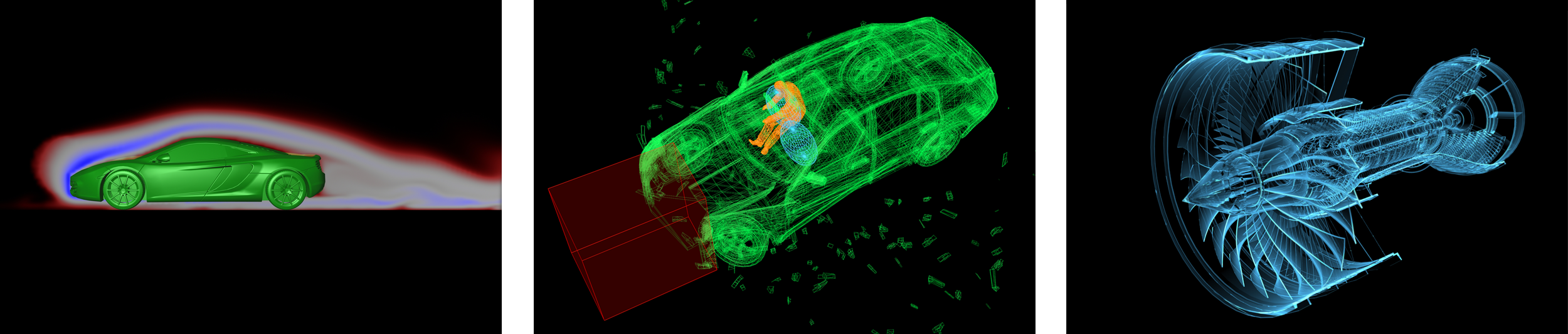

The versatility of the method has made finite element analysis an important tool for the design of many products. Nowadays, you cannot imagine designing a new product without using FEA. Its capabilities are such that it is widely used in many industries:

- Aerospace

- Automotive

- Rail

- Shipbuiding

- Consumer products (household appliances, sporting goods, toys...)

- Electronics

- Energy (wind turbine, nuclear, pipeline, solar panels, turbines...)

- Machinery

- Medical (orthopedic, prosthetics, implants, heart valves, medical fasteners...)

- Heavy equipments

- Packaging

Finite element analysis proved its versatility and reliability over the past 50 years in the developement of a multitude of products. Currently, with the development of High Processing Computing (HPC) and the progress of computing capabilities, FEA establishes itself as an important tool in the design and production of innovative, highly-efficient and more reliable products.

FEA is used for predicting the response of structures to environmental factors such as forces, pressure, thermal, vibrations… With FEA, it is possible to predict how a product will behave in the real world in terms of whether it will break. It permits also to predict the weakest points of the product and verify if it will work the way it was designed.

FEA is an important part of a product design and development process because it saves engineers time and effort needed to build a physical prototype. Prototype tests do not provide the type of numerical information that FEA does, making the product development process longer. FEA saves time and effort for engineers since they can iterate on the design based on FEA calculations without building costly prototypes.

Nowadays, even the simplest products rely on the finite element method for design evaluation. This is because contemporary design problems cannot be solved as accurately and cheaply using any other method that is currently available. Physical testing was the norm in years gone by, but now it is simply too expensive. It is impossible to imagine a product designed without the help of FEA. Most of the common products we use every day have been engineered with the help of FEA.

-

Before to define the product: FEA helps the engineer to create a feasible design

-

After the product is designed: FEA permits to validate the defined design

-

After the product is released: FEA can be used to investigate the failures of the product